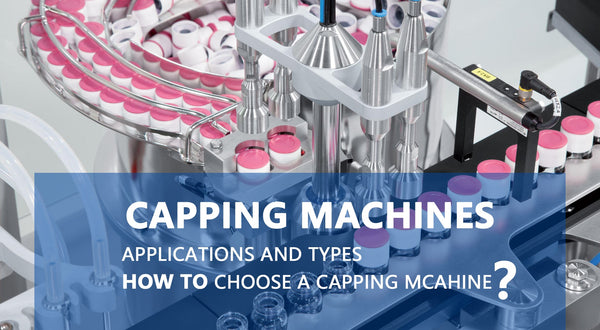

Capping Machines: Applications and Types How to choose a capping mcahine

Capping machines are essential pieces of equipment used in the packaging industry to seal various types of bottles, jars, and containers. They come in different types, including manual, semi-automatic, and fully automatic models, and are widely used in industries such as cosmetics, food and beverages, pharmaceuticals, and more. Here are some examples of their applications:

-

Perfume Bottles: Capping machines are commonly used in the cosmetics industry to seal perfume bottles. These machines can handle a wide range of bottle sizes and shapes, and can apply different types of caps, including screw caps, snap-on caps, and more.

-

Cans: Can capping machines, also known as can sealing machines, are used to seal cans for products such as food, beverages, and aerosol sprays. These machines can handle a variety of can sizes and shapes, and can apply different types of seals, including pull-tab lids, easy-open lids, and more.

-

Soda Bottles: Capping machines are used to seal soda bottles with screw caps or snap-on caps. These machines are designed to handle high-speed production lines and can apply caps to a large number of bottles per minute.

-

Spray Bottles: Capping machines are also used to seal spray bottles, commonly used in the pharmaceutical and cosmetics industries. These machines can apply different types of triggers or sprayers, including mist sprayers, pump sprayers, and more.

Capping machines can come in different types, depending on the level of automation required. Here are the three types of capping machines:

-

Manual Capping Machines: These machines require manual labor to apply caps to bottles. They are simple to operate and are ideal for small-scale production lines.

-

Semi-Automatic Capping Machines: These machines require minimal operator intervention and use pneumatic or electric motors to apply caps to bottles. They are suitable for medium-scale production lines.

-

Fully Automatic Capping Machines: These machines are highly automated and can handle high-speed production lines. They use sensors and PLC controls to apply caps to bottles, and can handle a wide range of cap and bottle types.

In conclusion, capping machines are essential pieces of equipment in the packaging industry, with a wide range of applications in different industries. They come in different types, including manual, semi-automatic, and fully automatic models, and can handle different types of caps and bottles. Whether you're in the food and beverage, cosmetics, or pharmaceutical industry, there's a capping machine that can meet your needs.